Our aim in developing the Air Force Two Premium was to achieve almost the same level of musicality as our flagship the Air Force One. To this end we looked at the material of the main platter. The Air Force One uses a stainless steel main platter while the standard Air Force Two uses a platter made of aluminum. Since the beginning of the standard Air Force Two, it has been found that the difference in material of the platter is even more critical for tonality than the difference in weight. This is why we began testing new materials.

As a result of various experiments, gunmetal was chosen for the platter of the Air Force Two Premium. This material is an alloy of copper and tin, and was often used in audio equipment in the heyday of analog audio. As gunmetal is relatively soft and tensile, a subtle glow is added to the sound while its heavy weight further increases the scale of the sound stage.

The platter for the Air Force Two Premium is precision cast and surface polished with a solid construction, unlike most conventional gunmetal platters that have a hollow construction. The result is a platter of huge mass, some 34 kg.

Technology used in vinyl reproduction

Descended from the flagship model, the core mechanism contained in the exquisite design concept is designed in such a way to exploit the aerodynamic force equivalent to sound energy to the full. It is a well-known fact that an analog disc is a sensitive and very fragile program source in which waveforms transmitted as air vibrations generated by the original music are imprinted into a microgroove in the record.

The turntable should thus be the key center of the playback process by extracting the original oscillatory waveforms in an authentic way and transmitting these as accurate audio signals. Any signals other than these valuable micro waveforms imprinted on the disc ought to be detected by a stylus as maleficent without exception.

There are specific examples such as frictional vibrations caused by bearings under a rotating turntable platter, vertical vibrations of a tonearm caused by warpage of an analog disc, or vibrations due to some stylus movement resonating with an even flat disc to the contrary and in addition to them, direct vibrations from the floor propagating directly through a turntable. There are surprisingly a constellation of maleficent vibrations. In early turntable design various attempted procedures have been rendered such as improved machining method for bearings, putting a stabilizer weight on the disc plate to reduce warpage and resonance, and supporting the overall player on springs. As a result, it is a fact that no one could accomplish their objectives until today.

The air bearing & disc suction

The Air Force Two Premium shares two major core technologies with the other Air Force turntables: Air bearing and vacuum LP hold-down.

Accurate, noise-free and stable rotation is always the key to turntables. To fulfil such a precision rotation, because greater mass provides more inertia, any quality turntable needs a massive platter. The gunmetal platter of the Two Premium weighs 33 kg. With a conventional bearing design, such a heavy platter would put so much load on the bearing it would cause deterioration of the bearing system over time and generates friction vibrations to degrade the accuracy in rotation.

The Air Force Two Premium has no such issues thanks to it’s air bearing, one of the trickle-down technologies from the Air Force One Premium. With every model of the Air Force range the platter is installed on the smooth and polished glass surface aligned with the center shaft for positioning. The platter sits still on the glass surface when the system is not activated. Once the air pumps in a separate chassis are activated with the system turned on, the platter will float instantly to the height of 0.03 mm (30μ) above the glass base and starts rotating quietly and smoothly. No load is applied to the bearing, and noise generated by friction or any kind of vibrations are eliminated. This has led to the highest level of sound quality and perfect performance.

The other key pneumatic technology is vacuum disc suction. Even if the platter is rotating in an extremely quiet manner and with maximum accuracy, a warped record may generate a vertical motion in the tonearm and cause an undesired stylus movement, causing vibrations. Under such circumstances, no musical signal can be extracted from a disc with absolute fidelity. Due to vertical motions of the tonearm, the stylus will be also affected. Resonant vibrations on the disc may lower the quality and sensitivity of the musical signal. The use of a record clamp is often recommended as a solution to the warped record issues but it would not entirely resolve these issues.

With vacuum LP hold-down, it takes just one press on the SUCTION button on the control panel to firmly hold down the record onto the platter. Then the platter and record rotates precisely at the rated speed you have selected. With vacuum LP hold-down, it is possible to extract every musical signal embedded in the groove with high fidelity. To release suction, press the suction button again, and the disc will be released instantly.

A new hybrid suspension system

The air suspension system employed in the Air Force One has top-level vibration insulation properties, but it requires occasional air filling and some level adjustment, which might be inconvenient to some people. In designing the Air Force Two Premium, we redesigned the suspension system to address this issue, with a focus on making it maintenance free while preserving the same level of properties. At the same time, this new suspension system is designed to accommodate the weight of the deck and to distribute the weight properly among its four feet.

This unique suspension system consists of an air chamber on the top and a rubber diaphragm in the middle enclosing a spring and oil within. This diaphragm is connected through a small hole with the top chamber and any vibrations from the floor are damped by oil inside the diaphragm and air in the chamber. As a result the system has excellent vibration insulation.

A precisely flat hard glass face is used under the platter, and air flow creates a 30 micron clearance between the platter and the glass face.

The most challenging task in designing the Air Force Two Premium was to achieve a significant cost reduction while preserving as much of the performance of its big brother Air Force One Premium as possible.

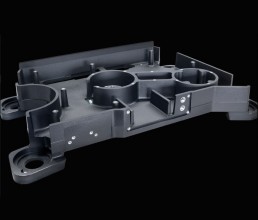

The precision cast aluminum chassis is the key to the successful cost reduction without sacrificing almost any of performance.

To achieve this goal, this model has a precision cast aluminum (AC4C) chassis in dark grey hammertone coating. This allows the chassis to have sufficient weight to maintain stable sound reproduction. The chassis consists of two separate pieces and weighs 32.6kg in total, which provides a firm platform for energetic music reproduction. The heavyweight platter is driven using a non-flexible polyurethane fiber belt.

The Air Force Two Premium has two DC power amplifiers to drive its high-precision AC synchronous motor housed in a free-standing rugged aluminum case. It also comes with a Pump / Power Supply /Air Condenser Unit. This unit has an integrated microprocessor to control the rotation speed of the platter through a speed sensor, and to maintain a constant rotation speed.

The Air Force Two Premium can be fitted with two tonearms. It accommodates almost any tonearm of either long or short length. Normally 9 or 10 inch short tonearms can be mounted on both positions of the right side and the left rear side of the unit while 12 inch tonearms can be fitted on the left rear position.

| MAIN UNIT & MOTOR | |

| Chassis | Cast aluminum alloy (AC4C) Dark gray hammertone coating |

| Weight | 33 kg |

| Platter | Gunmetal Surface protection coating |

| Platter Weight | 33 kg |

| Total moment of inertia | 4,148 kg・cm2 |

| Drive System | Belt-drive, polished and nonflexible polyurethane fiber belt |

| Motor | AC synchronous motor Rotation speed controlled by DC amplifiers |

| Rotation speed | 33.3 rpm / 45 rpm Precise speed adjustment function |

| Wow & Flutter | below 0.03 % |

| Dimensions | 684 (W) x 176 (H) x 450 (D) mm |

| Minimum Dimensions for setting up | 684 (W) x 460 (D) mm |

| Total Weight | 71 kg |

| PUMP / POWER SUPPLY/ AIR CONDENSER UNIT | |

| Power consumption | 50 W |

| Dimensions | 430 (W) x 175 (H) x 370 (D) mm |

| Weight | 14.5 kg |

| Minimum depth for setting up | 430 (D) mm |

| ACCESSORIES | |

| ACCESSORIES SUPPLIED | Tonearm base x 1 (drilled for specified tonearm). An extra cost may be required according to the tonearm. Platter Cover x 1. Cables, Air hoses, Platter setup tools, Users manuals. |

| OPTIONAL ITEMS & ACCESSORIES | Extra tonearm base. Disc Stabilizer. Exclusive rack manufactured by Artesania Audio. |